Menu

Menu

Address:16th floor, Science and Technology Incubator Building, Wuhan Institute of Technology, Huquan Street, Hongshan District, Wuhan City, Hubei Province

Investment hotline:4007162616

Company email:2686490776@qq.com

Company website:www.whty2005.com

Company Postal Code:430074

position:Home > Product Center

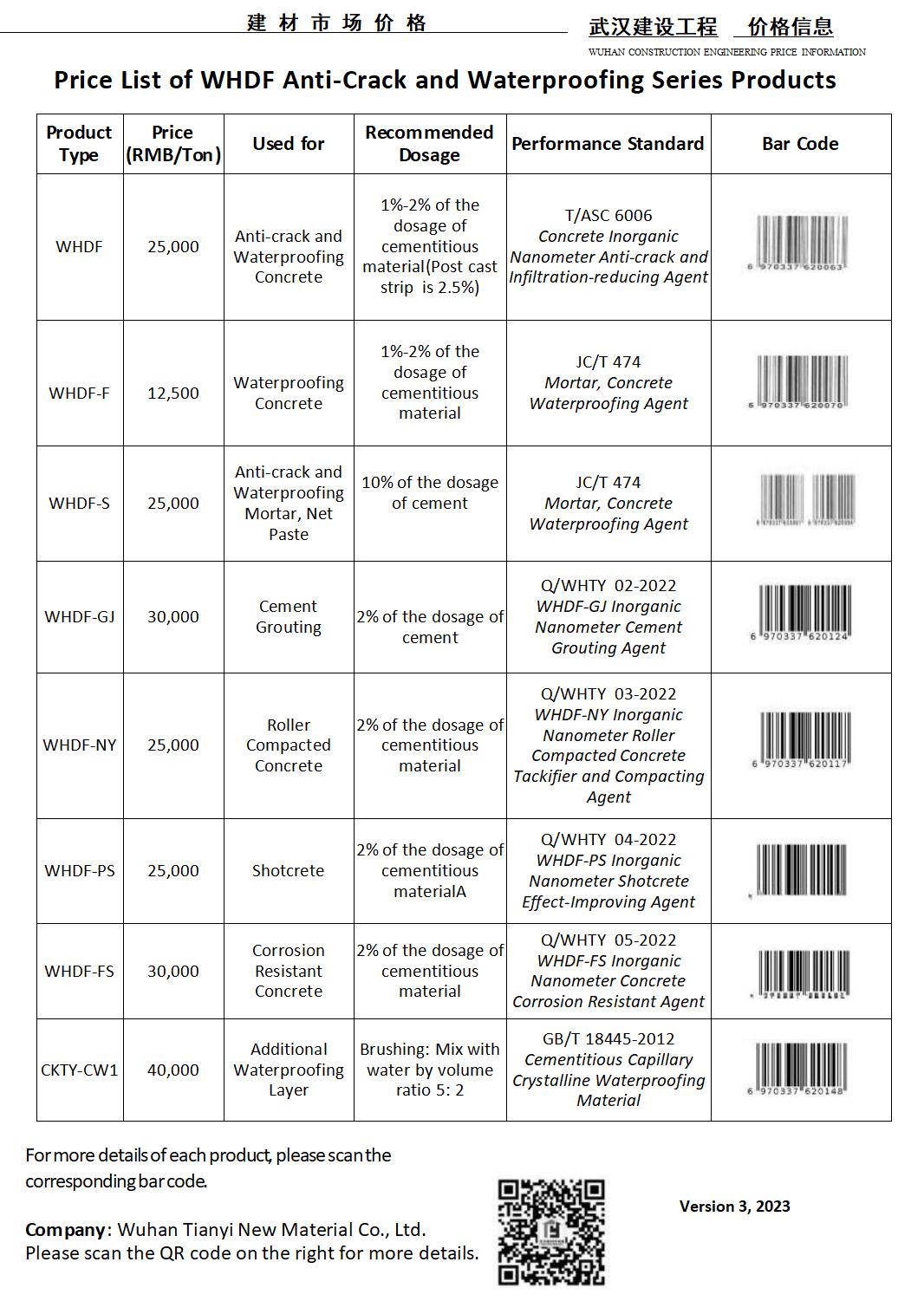

The name of this product is WHDF-PS Inorganic Nanometer Shotcrete Effect-improving Agent (referred to as WHDF-PS), which is an ionic colloid composed of inorganic nanomaterials. After adding it into the shotcrete, it can effectively improve the working performance of the shotcrete, reduce the shrinkage deformation of hardened concrete and improve the mechanical property, tensile strength, impermeability and bonding performance of shotcrete.

4007162616 Online price inquiryThe ionic colloid composed of inorganic nanomaterials can effectively improve the working performance of the shotcrete, reduce the shrinkage deformation of hardened concrete and improve the mechanical property, tensile strength, impermeability and bonding performance of shotcrete.

It is suitable for structural reinforcement and repair works for underground engineering, protection of the geotechnical engineering and other fields, such as the primary lining and secondary lining of tunnel, etc.

The recommended WHDF-PS amount is 2% of cementitious material dosage, and the specific amount should be determined according to the actual requirements of the project.

The construction requirements of anti-cracking and waterproofing concrete with WHDF-PS are as follows :

1.Keep the formwork and bedding clean and wet.

2.Check the concrete materials delivery list and the concrete mix ratio. Confirm the concrete strength grade. Check the concrete transportation time. Determine the concrete slump and measure the concrete extension if necessary , and then carry out concrete pouring after all the confirmation.

3.It is better to carry out the continuous pouring of concrete at one time; When continuous pouring is not available at one time, the interval time should not exceed 1.5 hours.

4.The process of pouring the concrete should be carried out layers by layers, which should meet the specified requirements for the vibration thickness, and the upper concrete should be poured before the initial setting of the lower concrete.

5.Concrete vibrating should be able to make the concrete in all parts of the formwork dense and uniform. There should be no incomplete vibration, undervibration, overvibration, and slurry leakage in order to avoid the honeycomb.

6.The maintenance should be carried out as soon as possible after the pouring is done, and the maintenance period should not be less than 14 days.

This product is non-toxic,non-flammable,non-explosive and non-volatile. Store at room temperature and room pressure in the warehouse; There are no special requirements for the transportation; It is valid for one year.

Shake the product well before use; Do not mix the WHDF-PS stock solution directly with water reducer or other admixtures.