Menu

Menu

Address:16th floor, Science and Technology Incubator Building, Wuhan Institute of Technology, Huquan Street, Hongshan District, Wuhan City, Hubei Province

Investment hotline:4007162616

Company email:2686490776@qq.com

Company website:www.whty2005.com

Company Postal Code:430074

position:Home > Product Center

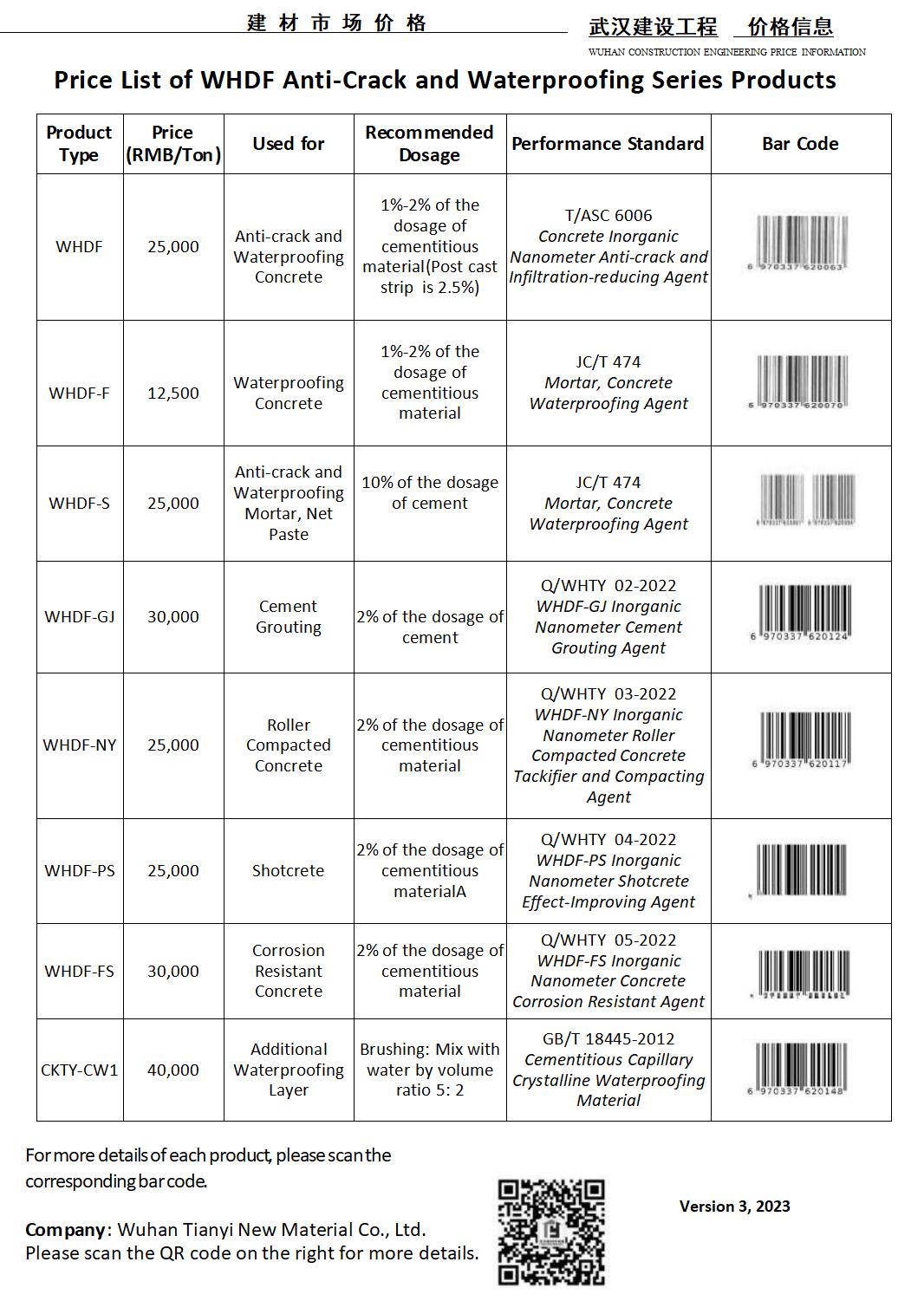

The name of this product is WHDF-F Concrete Inorganic Nanometer Waterproofing Agent. (referred to as WHDF-F)

4007162616 Online price inquiryThe product is composed of nano-scale inorganic salt. Through a series of chemical reactions, the hydration process of cementitious materials in concrete is optimized, which increases the gel in the concrete and decreases the porosity, so to achieve the purpose of improving interface structure of the cement slurry-aggregate. The concrete added with WHDF-F has good compactness property and can greatly improve the self-waterproof ability of concrete.

1.Compactness Property: After adding WHDF-F(the amount is 1-2% cementitious materials), the impermeability grade of concrete can reach to P6 or P8, which meets the requirements of most construction projects for the impermeability of concrete structures.

2.Working Property: After adding WHDF-F, the gel in the concrete system increases, and the plastic viscosity of concrete mixture increases accordingly. There is no segregation and no bleeding in the fresh concrete, which can ensure no blocking during the construction pumping and a smooth construction progress.

It is suitable for all the construction projects with high crack-resistance and waterproofing requirements for concrete, including but not limited to the following projects:

1.The self-waterproofing of concrete in dams and underground construction facilities of Hydraulic and Hydropower Engineering .

2.The self-waterproofing of concrete in Military & Nuclear Underground Engineering.

3.The self-waterproofing of concrete in Transport Construction Engineering such as roads, railways, bridges, wharves, subways and tunnels under the sea.

4.The self-waterproofing of concrete in Municipal Engineering such as tap water and sewage treatment projects.

5.The self-waterproofing of concrete in Civil Construction Engineering such as basements, kitchens, bathrooms and cast-in-place of roof.

The recommended WHDF-F amount is 2% of cementitious material dosage, and the specific amount should be determined according to the actual requirements of the project.

The construction requirements of anti-cracking and waterproofing concrete with WHDF-F are as follows :

1.Keep the formwork and bedding clean and wet.

2.Check the concrete materials delivery list and the concrete mix ratio. Confirm the concrete strength grade. Check the concrete transportation time. Determine the concrete slump and measure the concrete extension if necessary , and then carry out concrete pouring after all the confirmation.

3.It is better to carry out the continuous pouring of concrete at one time; When continuous pouring is not available at one time, the interval time should not exceed 1.5 hours.

4.The process of pouring the concrete should be carried out layers by layers, which should meet the specified requirements for the vibration thickness, and the upper concrete should be poured before the initial setting of the lower concrete.

5.Concrete vibrating should be able to make the concrete in all parts of the formwork dense and uniform. There should be no incomplete vibration, undervibration, overvibration, and slurry leakage in order to avoid the honeycomb.

6.The maintenance should be carried out as soon as possible after the pouring is done, and the maintenance period should not be less than 14 days.

Table 3. Property of Concrete with WHDF

|

Testing Items |

Property Index |

||

|

First-class quality |

Qualified products |

||

|

Stability |

Qualified |

Qualified |

|

|

Ratio of bleeding rate, % ≤ |

50 |

70 |

|

|

Difference in setting time, min ≥ |

Initial set |

-90* |

-90* |

|

Compressive strength ratio, % ≥ |

3d |

100 |

90 |

|

7d |

110 |

100 |

|

|

28d |

100 |

90 |

|

|

Penetration height ratio, % ≤ |

30 |

40 |

|

|

Water absorption ratio (48h), % ≤ |

65 |

75 |

|

|

Shrinkage ratio (28d), % ≤ |

125 |

135 |

|

|

Note 1: Stability is the testing result of the tested slurry, the setting time difference is the difference value between the concrete with WHDF and the concrete without WHDF, and the other data in the table is the ratio of the concrete with WHDF to the concrete without WHDF. Note 2: *"-" sign means ahead of the time. |

|||

This product is non-toxic,non-flammable,non-explosive and non-volatile.Store at room temperature and room pressure in the warehouse; There are no special requirements for the transportation.

Shake the product well before use; Do not mix the WHDF-F stock solution directly with water reducer or other admixtures.