Menu

Menu

Address:16th floor, Science and Technology Incubator Building, Wuhan Institute of Technology, Huquan Street, Hongshan District, Wuhan City, Hubei Province

Investment hotline:4007162616

Company email:2686490776@qq.com

Company website:www.whty2005.com

Company Postal Code:430074

position:Home > Product Center

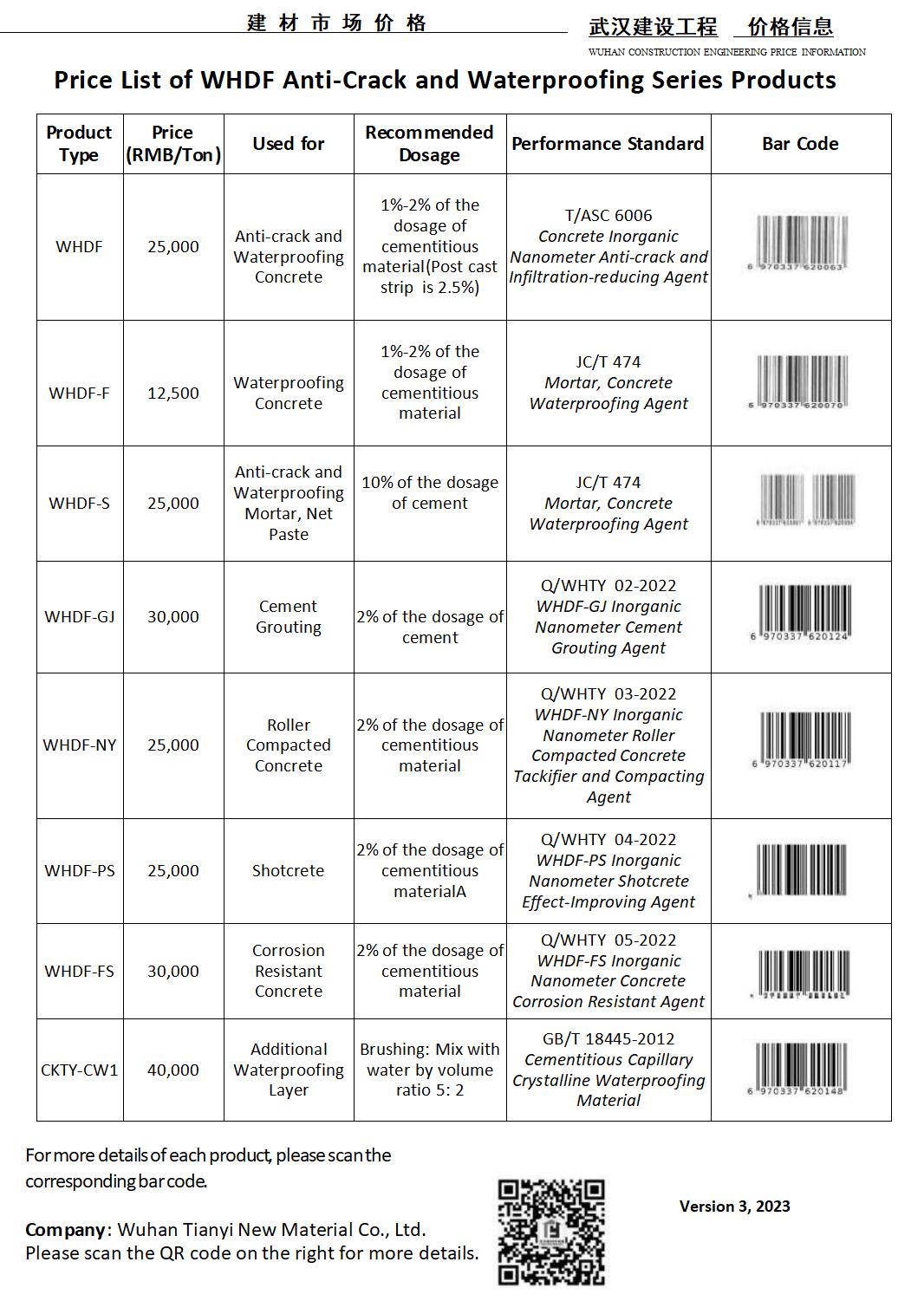

According to the different application conditions and environment, Wuhan Tianyi New Material Co.,Ltd has developed WHDF series products on the basis of WHDF Concrete Inorganic Nanometer Anti-crack and Infiltration-reducing Agent, including WHDF-S Mortar Inorganic Nanometer Waterproofing Agent.

4007162616 Online price inquiryUnder the combined action of Nano dispersant, Aluminum-calcium inhibitor and Crystalline activator, the WHDF-S Mortar Inorganic Nanometer Waterproofing Agent can promote the cement hydration degree in cement mortar, optimize hydration products, inhibit early rapid hydration of C3A and reduce early hydration heat, so that the gel of the system increases, the porosity decreases, and early hydration heat decreases. In addition to significantly improving the crack resistance, impermeability and durability of mortar, the bond stress of mortar can be effectively improved to achieve the purpose of waterproofing and impermeability.

It is suitable for all the construction projects with high bond stress and waterproofing requirements for mortar, including but not limited to the following projects:

1.Adhesive treatment for anti-bleach mortar and facing on exterior wall.

2.Waterproofing treatment for basements, swimming pools, ponds,etc.

3.Installation and treatment of the water pipe connections.

4.Waterproofing treatment for home decoration sections, such as kitchens, toilets, balconies, facing layers,etc.

1.Preparation of admixture: Mix WHDF-S stock solution and clean tap water at the weight ratio of 1:4 into the admixture.

2.Preparation of waterproofing mortar:

a. Manually mixing: Mix cement and medium-fine sand at a ration of 1:3 (the cement-sand ratio is determined according to the design requirements). After mixing evenly, add the prepared admixture into it and mix all together into glutinous mortar

b. Mechanically mixing: Add WHDF-S stock solution at 10% of the weight of cement per tank, and then Mix with water and stir it together evenly. (The amount should be adjusted according to the construction progress)

1.The base surface should be smooth, solid, clean, and should be fully moistened without clear water.

2.The holes and gaps on the surface of the base layer should be blocked and smoothed by the anti-cracking and waterproofing mortar same as the waterproof layer.

3.Before construction, the embedded parts and the groove reserved for wall pipe should be filled with sealing material, and then start the construction of the waterproof layer of anti-cracking and waterproofing mortar.

4.The waterproof layer of anti-cracking and waterproofing mortar should be spread or sprayed in layers, and each layer should be thinner than 10mm. When spreading, the layer should be smoothed and compacted, and the surface of the last layer should be pulped and glazed.

5.Each layer of anti-cracking and waterproofing mortar should be tightly bonded, and each layer should be constructed in succession; When the construction joint must be reserved, the slope croucher should be applied, but the distance from the internal and external corner shall be no less than 200mm.

6.After the waterproof layer of anti-cracking and waterproofing mortar is finally solidified, it should be maintained in time. The maintenance temperature should not be lower than 5℃, the surface of the mortar should be kept wet, and the maintenance period should be no less than 14 days.

Table 1. Property of Concrete with WHDF-S

|

Testing Items |

Property Index |

||

|

First-class quality |

Qualified products |

||

|

Stability |

Qualified |

Qualified |

|

|

Setting time |

Initial set, min > |

45 |

45 |

|

Final set, h < |

10 |

10 |

|

|

Compressive strength ratio, % > |

7d |

100 |

85 |

|

28d |

90 |

80 |

|

|

透水压力比 % > |

300 |

200 |

|

|

Water absorption ratio (48h), % < |

65 |

75 |

|

|

Shrinkage ratio (28d), % < |

125 |

135 |

|

|

Note 1: Stability is the testing result of the tested slurry, the other data in the table is the ratio of the concrete with WHDF-S to the concrete without WHDF-S. |

|||

This product is non-toxic,non-flammable,non-explosive and non-volatile. Store at room temperature and room pressure in the warehouse; There are no special requirements for the transportation; It is valid for one year.

Shake the product well before use; Do not mix the WHDF-S stock solution directly with water reducer or other admixtures.

previous article:CKTY-CW1/CW2 Cementitious Capillary Crystalline Waterproofing Material (CKTY-CW1/CW2)

next article:no more

Return